Why Hearing Conservation Programs Matter at Work

Every year, millions of workers lose their hearing-not from aging, not from music, but from the noise of their job. Think about it: a jackhammer, a printing press, a factory line, even a busy warehouse with forklifts and conveyor belts. These aren’t quiet places. And if you’re exposed to noise at or above 85 decibels for eight hours a day, your hearing is at risk. That’s the threshold where the law says your employer must step in. This isn’t optional. It’s required by OSHA under 29 CFR 1910.95, and it’s called a hearing conservation program.

Many people assume hearing loss is just part of getting older. But occupational hearing loss is preventable. In fact, studies show that when hearing conservation programs are done right, they reduce hearing loss by 30% to 50%. That’s not just good for workers-it’s good for business. Companies with strong programs report 5% to 10% higher productivity and 15% to 20% fewer absences. Why? Because workers aren’t struggling to hear instructions, missing safety cues, or dealing with constant tinnitus.

What the Law Requires: The Five Core Pieces

OSHA doesn’t leave this up to guesswork. If your workplace hits or exceeds 85 dBA over an 8-hour shift, you must have a full hearing conservation program. And it has to include five things: noise monitoring, audiometric testing, hearing protection, training, and recordkeeping. Skip any one of them, and you’re violating federal law.

Noise monitoring is where it starts. Employers must use calibrated sound level meters or noise dosimeters to measure exposure. This isn’t a one-time check. Every time you change equipment, add a new machine, or rearrange the floor layout, you need to retest. If noise levels go up, the program must adapt.

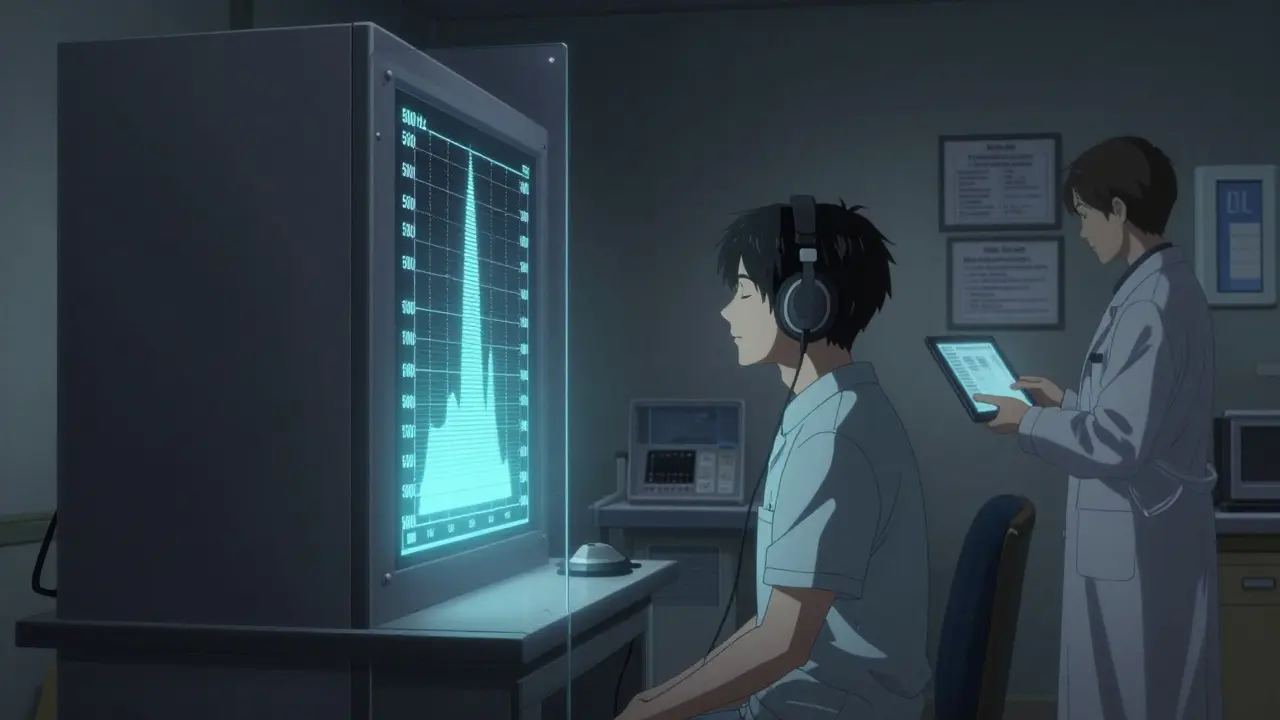

Audiometric testing is the health check for your ears. Every new employee exposed to 85 dBA or more gets a baseline audiogram within six months. But here’s the catch: they must be out of noisy environments for at least 14 hours before the test. Otherwise, the results are useless. After that, they get tested every year. The test checks hearing at 500, 1000, 2000, and 3000 Hz-critical frequencies for understanding speech. The room must meet strict background noise standards (OSHA Appendix C), and the audiometer must be calibrated to ANSI S3.6-2018 (not the old 1969 version, which is being phased out).

Hearing protection isn’t just handing out earplugs. Employers must offer a choice: foam plugs, silicone plugs, or earmuffs. And they must train workers on how to insert them correctly. A poorly fitted earplug can drop protection from 30 dB to just 5 dB. That’s the difference between safety and damage. The goal? Reduce exposure to 90 dBA or lower. But OSHA is moving toward stricter standards-by 2025, employers may need to protect against exposures above 100 dBA, not just cap it at 90 dBA.

Training happens every year. It’s not a one-hour video you watch and forget. Workers need to understand how noise damages hearing, why protectors matter, and what the test results mean. Many workers don’t realize that hearing loss is permanent. Once the hair cells in your inner ear are gone, they don’t come back.

Recordkeeping is the paper trail. Noise exposure records must be kept for two years. Audiograms? Those stay for the entire length of the employee’s employment. If someone leaves and comes back five years later, the employer must still have their original baseline.

What Happens When Hearing Loss Is Detected

Annual tests don’t just track hearing-they catch problems early. If an employee’s hearing drops by 10 dB or more at 2000, 3000, and 4000 Hz compared to their baseline, that’s called a Standard Threshold Shift (STS). It’s a red flag.

When an STS is found, the employer has 30 days to act. First, they must notify the employee in writing within 21 days. Then they must retrain the worker on how to use hearing protection. They must offer better protectors if needed. And if the shift is sudden, unexplained, or paired with dizziness or ear pain, the worker must be referred for a clinical audiological evaluation. This isn’t just paperwork-it’s a medical intervention.

Here’s something people don’t talk about: the baseline can be revised. If a professional audiologist determines the STS is permanent and not a one-time fluctuation, the employer can update the baseline. That prevents the same person from being flagged year after year for the same loss. But this isn’t a loophole-it’s a correction based on expert judgment.

Why So Many Programs Fail

OSHA issued over 1,800 citations for hearing conservation violations in 2022. That’s up 17% from 2020. And the biggest problems? Training and testing.

62% of violations were due to poor audiometric testing. Why? Because employers cut corners. They use uncalibrated machines. They test workers right after a noisy shift. They skip the 14-hour quiet period. They don’t use certified professionals. The results? False negatives. Workers think they’re fine, but their hearing is slowly disappearing.

28% of violations are about training. Employees aren’t told how to insert earplugs properly. They’re given cheap foam plugs and told to “just wear them.” They don’t know the difference between NRR (Noise Reduction Rating) and real-world protection. And they don’t understand that a 30 dB NRR doesn’t mean they’re protected from 100 dBA down to 70 dBA-it’s a lab number. Real-world protection is often half that.

Small businesses struggle the most. Companies with fewer than 50 employees have a 37% non-compliance rate. Why? Cost. A full hearing conservation program runs $250 to $400 per employee a year. Audiometric testing makes up nearly half of that. Many small employers think they can skip it. They can’t.

One of the biggest barriers? Employee participation. Nearly 70% of safety managers say workers skip their annual hearing tests. Some think it’s a waste of time. Others are afraid of what the results might show. Mobile testing units help-73% of compliant companies use them. They come to the site, save time, and increase attendance.

What’s Changing in 2025 and Beyond

OSHA is updating its rules. The old ANSI SC-1969 audiometer standard is being replaced with ANSI S3.6-2018. That’s not just a paperwork change-it means more accurate testing. Newer machines detect subtle hearing loss earlier.

They’re also expanding test frequencies. Right now, most tests stop at 3000 Hz. But hearing loss often starts at 4000 Hz and 6000 Hz. By 2025, employers may be required to test up to 6000 Hz. This could catch damage before it affects speech understanding.

Another big change: hearing protectors. The current rule only requires reducing noise to 90 dBA. But research shows that even 85 dBA over decades causes hearing loss in 8% to 12% of workers. The new proposal will require employers to match protection levels to actual exposure. If you’re exposed to 100 dBA, you need protectors that bring you below 90 dBA-not just to 90 dBA. That’s a major shift.

Industry experts predict these changes will prevent 150,000 new cases of hearing loss every year. But they’ll also raise costs by 8% to 12%. For small businesses, that’s a challenge. For workers? It’s a lifeline.

What You Can Do: A Quick Checklist

If you’re an employer:

- Test noise levels annually and after any equipment changes.

- Offer baseline audiograms within 6 months of exposure.

- Conduct annual tests in a quiet, calibrated room with certified professionals.

- Provide multiple types of hearing protectors and train workers on proper fit.

- Hold annual, interactive training-not a video and a signature.

- Keep records for the life of the employee.

- Act within 30 days if an STS is detected.

- Consider mobile testing units to boost participation.

If you’re an employee:

- Show up for your hearing tests-even if you think you’re fine.

- Ask how to insert your earplugs correctly. Watch a video. Practice in front of a mirror.

- Speak up if your protectors are uncomfortable or don’t seem to help.

- Don’t assume your hearing is okay because you can still talk. Hearing loss often starts with high-pitched sounds-birds, alarms, doorbells.

- Know your rights. You’re entitled to a copy of your audiogram.

Final Thought: Hearing Is Irreplaceable

There’s no cure for noise-induced hearing loss. No pill, no surgery, no device can restore what’s gone. Once the inner ear is damaged, it’s permanent. That’s why hearing conservation isn’t about compliance-it’s about preserving your ability to hear your child laugh, your partner’s voice, music, birdsong, silence.

Employers who treat this as a legal checkbox are missing the point. The best programs don’t just avoid fines-they build a culture where workers feel seen, protected, and valued. That’s not just good safety. That’s good business.

What noise level triggers a hearing conservation program?

A hearing conservation program is required when employees are exposed to noise at or above an 8-hour time-weighted average of 85 decibels (dBA). This is called the "action level" under OSHA’s 29 CFR 1910.95. At this level, employers must begin noise monitoring, provide hearing protection, and offer audiometric testing.

How often must audiometric testing be done?

Employees exposed to 85 dBA or higher must receive a baseline audiogram within six months of initial exposure. After that, annual audiograms are required. The test must be conducted in a quiet room, using calibrated equipment, and the employee must be free from workplace noise for at least 14 hours before the test.

What is a Standard Threshold Shift (STS)?

An STS is a change in hearing sensitivity of 10 dB or more, averaged across 2000, 3000, and 4000 Hz, compared to the employee’s baseline audiogram. It signals possible noise-induced hearing loss. When detected, employers must notify the worker in writing within 21 days and take corrective actions within 30 days, including retraining and offering better hearing protection.

Can an employer make employees pay for hearing protection?

No. OSHA requires employers to provide hearing protectors at no cost to employees. This includes all types-earplugs, earmuffs, and custom-molded options. Employers must also provide replacement protectors as needed. Charging employees for these items is a violation of federal safety regulations.

Are there alternatives to traditional earplugs and earmuffs?

Yes. Advanced options include electronic hearing protectors that amplify quiet sounds while blocking loud noises, custom-molded earplugs for better fit and comfort, and communication headsets that allow speech clarity while reducing hazardous noise. Employers must offer a variety of options to ensure proper fit and employee acceptance.

What happens if an employee refuses to wear hearing protection?

Employers must still provide protection and training, but they can enforce use through workplace safety policies. Refusal to wear protection in designated areas may result in disciplinary action, including temporary removal from noisy areas. The goal isn’t punishment-it’s prevention. Repeated refusal may trigger a review of training methods or protection options to find what works for the individual.

Is hearing loss from work covered by workers’ compensation?

Yes. Noise-induced hearing loss is recognized as a compensable occupational illness in all U.S. states. Workers can file claims for hearing aids, medical evaluations, and lost wages if hearing loss is proven to be work-related. Documentation from a qualified audiologist and employer audiometric records are key to a successful claim.

Milla Masliy January 14, 2026

My dad worked in a steel mill for 38 years. He never complained about the noise until he couldn’t hear my kids laugh at Thanksgiving. That’s when he finally got his hearing aids. If only the company had done more back then. This post? It’s not just compliance-it’s about people. Don’t wait for the silence to hit you.

Damario Brown January 15, 2026

lol osha is just a tax on small biz. nobody cares about 85 dba. i worked in a warehouse and my ears were fine. they just want to make you buy fancy ear muffs so they can charge more. also audiograms are a scam. my cousin got flagged for sts but he just had a cold. dumb.

sam abas January 17, 2026

Let’s be real here. The entire OSHA framework around hearing conservation is built on outdated assumptions. The 85 dBA threshold? That’s from the 70s. Modern studies show that even 75 dBA over prolonged exposure can cause cumulative neural fatigue, especially in younger workers whose auditory pathways are still developing. And don’t get me started on the NRR-those numbers are lab-tested in anechoic chambers with perfect fit. In the real world? Half that, if you’re lucky. Plus, the 14-hour quiet period? Most workers clock out, grab a beer at the bar, and then show up for their test. The data’s garbage. We’re not protecting hearing-we’re just creating paperwork that looks good for auditors.

Adam Vella January 18, 2026

There is an ethical imperative here that transcends regulatory compliance. Hearing is not merely a physiological function-it is the conduit through which we experience human connection, emotional nuance, and the sublime quiet of existence. To reduce this to a cost-benefit analysis is to commodify the very essence of being. The employer who views this as a checkbox is not merely negligent-they are ontologically impoverished.

Clay .Haeber January 19, 2026

Oh wow, OSHA’s finally waking up? Took them long enough. Meanwhile, I’ve been wearing custom-molded earplugs with Bluetooth since 2019 so I can listen to audiobooks while operating a CNC machine. But sure, let’s keep pretending foam plugs and a 10-minute video count as ‘training.’ At this point, the only thing more dangerous than the noise is the HR department’s PowerPoint deck.

vishnu priyanka January 20, 2026

Man, this reminds me of my cousin in Chennai-he works in a textile factory with 100+ looms. No one there even knows what dBA means. They hand out cotton balls as ‘ear protection.’ I told him to get a pair of those cheap electronic plugs from Amazon. He said they cost more than his lunch. This ain’t just an American problem. Global labor needs better ears.

Trevor Whipple January 22, 2026

you think this is bad? wait till you see the guy who refuses to wear earplugs because he says 'it makes him feel like a robot' then sues the company when he goes deaf. yeah real hero. just wear the damn plugs and stop being a drama queen.

Lethabo Phalafala January 23, 2026

I worked in a meatpacking plant. The noise? It felt like your skull was being hammered from the inside. I didn’t miss a single test-not because I was scared, but because I didn’t want to wake up one day and not hear my daughter say ‘I love you.’ This isn’t about rules. It’s about love. And if your boss doesn’t get that, they’re not a boss-they’re a liability.

Lance Nickie January 24, 2026

85 dba? more like 90. they’re just stretching the numbers to make compliance look easier.

John Pope January 25, 2026

Here’s the real tragedy: we’re all just noise machines trying to survive in a world that never taught us how to listen. The earplugs? They’re not armor. They’re a metaphor. We drown in data, in alerts, in chatter-but we’ve forgotten how to hear silence. The real STS isn’t on the audiogram-it’s in our souls. We’ve lost the ability to be still. And no OSHA form can fix that.